As we stand on the threshold of a technological revolution, the arrival of 5G is set to redefine the landscape of industrial automation. We’ve seen significant advancements over the years, but nothing promises the level of transformation as 5G does. Imagine a world where machines communicate in real-time, where latency is a relic of the past, and where connectivity isn’t just fast but instantaneous. These are not just dreams—they are the realities that 5G is bringing to life. Let’s delve into how this network evolution is redefining the industrial realm, turning manufacturing sectors into hubs of smart systems and connected devices.

Unpacking the 5G Revolution in Industries

With the advent of 5G, industries are poised for a transformation unlike any seen before. Gone are the days when slow data transfer and high latency hindered effective automation. Today, 5G offers ultra-fast speeds and unprecedented responsiveness, making it the bedrock for smart manufacturing.

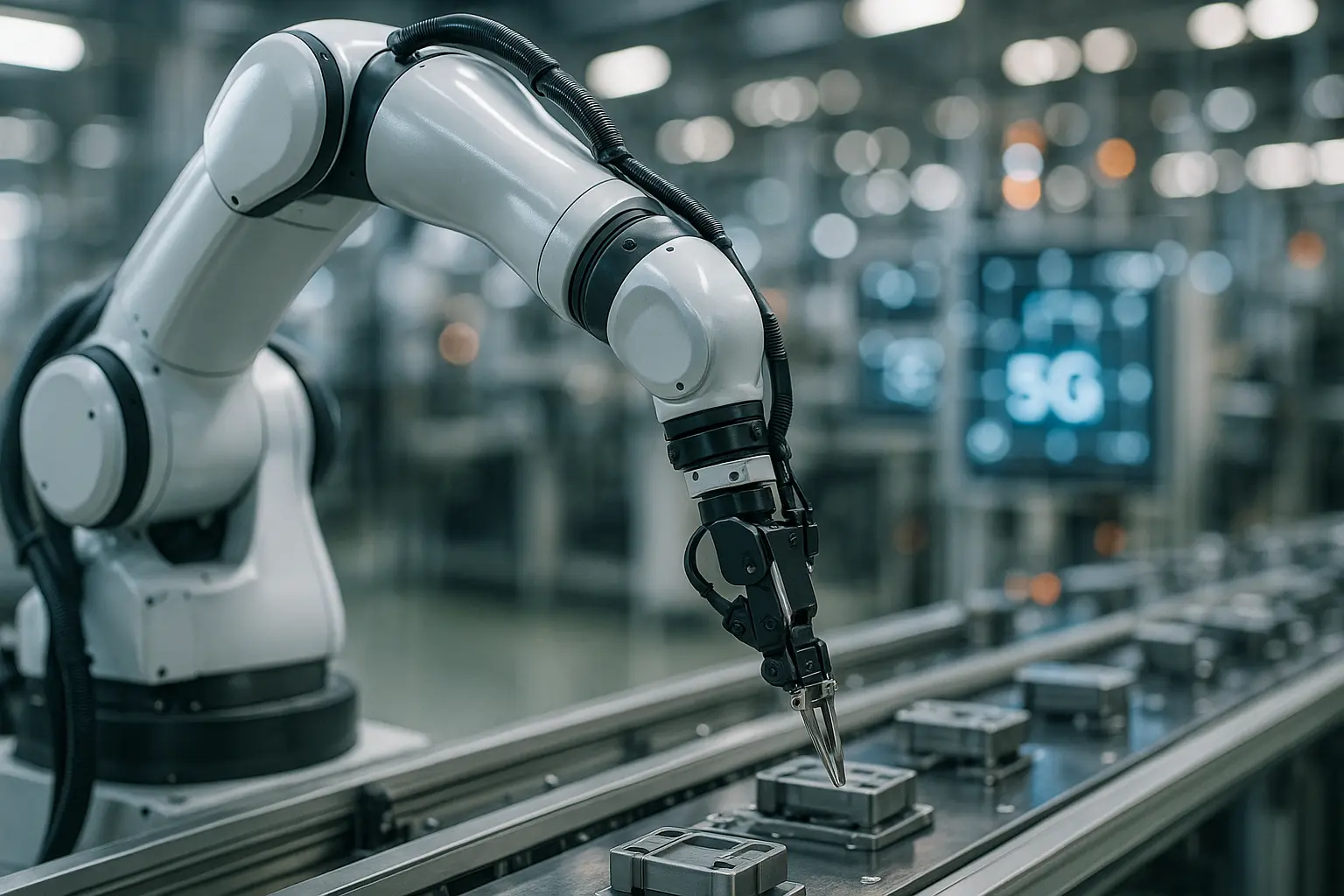

The shift to 5G means more devices can be connected at any given time without compromising on speed. This is vital for industrial automation, where precision and timeliness are crucial. Imagine a factory floor where machines can communicate instantly, adjusting to changes on the fly. With 5G, this isn’t just possible; it’s becoming the norm.

Moreover, 5G enhances network reliability, ensuring that critical systems remain operational even during peak times. This stability minimizes downtime, which directly impacts an industry’s bottom line. It’s not just about speed; it’s about creating a seamless, interconnected ecosystem.

Applications such as AI-driven quality control, predictive maintenance, and robotic assistance are now more efficient. With 5G, these systems can function as they were truly intended, analyzing, responding, and executing with a level of precision that was previously unattainable.

As we navigate this digital era, it’s clear that 5G is not just an incremental upgrade but a paradigm shift. It’s setting the stage for a future where automation is not just intelligent but intuitive, responding to the needs of the industry in real-time.

The Role of IoT in Revolutionizing Manufacturing

The fusion of 5G with the Internet of Things (IoT) is paving the way for a new age of smart manufacturing. In this networked world, every device, from sensors to heavy machinery, can communicate instantly, sharing data and insights that drive efficiency and innovation.

With IoT powered by 5G, we see a significant enhancement in real-time monitoring and autonomous operations. Consider a facility where sensors detect anomalies in production lines, and the system swiftly adjusts without human intervention. This automation isn’t just about speed; it’s about creating a responsive and adaptive environment.

Moreover, IoT devices, underpinned by the speed of 5G, can handle vast amounts of data with ease. This capability allows for sophisticated analytics, enabling industries to make informed decisions swiftly. Predictive maintenance, a dream for many manufacturers, becomes a reality. Machines can now anticipate failures before they happen, ensuring smooth operations and minimizing costly downtimes.

The integration of IoT and 5G also fosters innovative applications such as augmented reality (AR) for training and remote troubleshooting, offering an immersive and interactive approach to problem-solving. The potential of this synergy is immense, turning traditional manufacturing into a dynamic, connected ecosystem.

In this new paradigm, industries are not just adopting technology—they are evolving with it. The connectivity and capabilities offered by 5G and IoT are setting a new standard, one where automation is synonymous with innovation.

Overcoming Challenges with 5G Implementation

While the promise of 5G is exhilarating, its implementation in industrial settings is not without challenges. Transitioning to this advanced network involves overcoming several hurdles, from cost considerations to infrastructure upgrades.

First and foremost is the financial aspect. Upgrading systems to accommodate 5G requires a substantial investment. Manufacturers must weigh the benefits versus the initial costs. However, the long-term gains in efficiency, reliability, and speed make a compelling case for investment.

Another challenge is the integration of new technology with existing systems. Industries must ensure that their current infrastructure can support 5G’s capabilities. This may involve replacing outdated hardware or retrofitting existing equipment.

Security concerns also emerge as more data flows through connected devices. The increase in connectivity heightens the risk of cyber threats. Industries need to invest in robust cybersecurity measures to protect their networks and data from potential breaches.

Moreover, training personnel to handle new technologies is crucial. The shift to 5G is not just a technological change but a cultural one as well. Employees must be equipped with the skills to harness the full potential of this technology.

Despite these challenges, the benefits of adopting 5G outweigh the hurdles. The transition might be complex, but the end result is a more resilient, efficient, and future-proof industrial environment.

As we embrace the dawn of 5G, we find ourselves on the cusp of a new era in industrial automation. The speed, reliability, and connectivity it offers herald a transformation that will redefine how industries operate.

5G is not just an enhancement; it’s a revolution. It empowers industries to explore uncharted territories of innovation and efficiency. As we navigate this journey, we must remain vigilant, adapting to challenges while seizing opportunities.

This technology is reshaping manufacturing, turning it into a dynamic and responsive field. The future is bright, filled with possibilities limited only by our imagination. With 5G, we are not merely keeping pace with the world—we are setting the standard for the next generation of industrial innovation.

FAQ

What is 5G and how does it differ from previous generations of mobile networks?

5G, or fifth-generation wireless technology, is the latest iteration of cellular networks, offering significantly faster data speeds, lower latency, and the ability to connect a vast number of devices simultaneously compared to its predecessors like 4G and 3G.

How can 5G technology transform industrial automation processes?

5G technology can revolutionize industrial automation by providing ultra-reliable and low-latency communication, enabling real-time data transfer, remote monitoring, and enhanced machine-to-machine interactions. This can lead to more efficient operations and reduced downtime.

What are the potential benefits of adopting 5G in manufacturing environments?

Adopting 5G in manufacturing can enhance productivity through real-time analytics, improve safety with advanced monitoring systems, and allow for greater flexibility and scalability in operations by enabling seamless communication between devices and systems.

Are there any challenges industries might face when integrating 5G technology?

While 5G offers numerous advantages, industries may face challenges such as high initial infrastructure costs, the need for skilled personnel to manage and maintain 5G systems, and potential cybersecurity risks associated with increased connectivity.

How does 5G contribute to the development of smart factories?

5G facilitates the creation of smart factories by enabling seamless communication between IoT devices, robotics, and automation systems. This connectivity supports advanced manufacturing techniques, predictive maintenance, and improved supply chain management, driving innovation and efficiency in production processes.